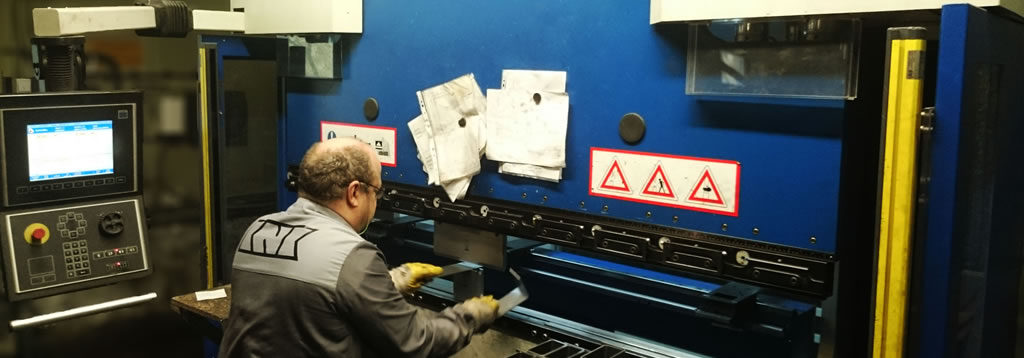

The main manufacturing program of the KNK NAKO company is the cold forming of steel and other metallic materials.

Steel and stainless steel sheets, profile steel and pipes, aluminum sheets and profiles of various sizes are processed by the manufacturing technologies of mechanical machining – cutting/separation, pressing, turning, milling, drilling, threading and welding.

Technical and decorative zinc alloy castings (ZAMAK 5) and plastics are manufactured by the technological process of pressure die casting into molds.

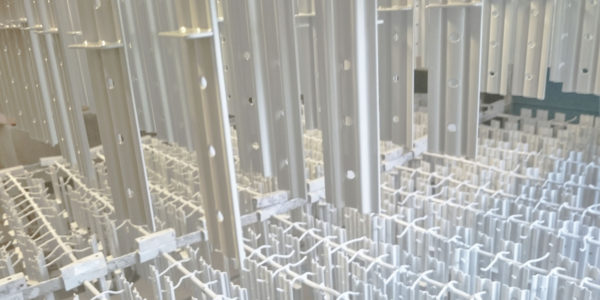

Preparation of products for surface treatment is proceed by finishing processes of grinding, deburring, satinizing or polishing as well as degreasing and cleaning technology (passivation). Unfinished products then enter the technological processes of surface finishing by galvanic coating or powder coating.

The final products are packed according to customer requirements into PE bags of different sizes and thickness, stretch foil or other packaging materials. Smaller products are usually packed into cartons, larger series are shipped in wooden pallet collars on euro pallets. Larger products of welded construction type are individually wrapped.

Tradition has packing of mounting fittings for the furniture in a dismantle into sealed perforated plastic bags.

For this purpose, we have created a special sheltered workshop and sheltered workplaces where we employ people with disablities.